Static Balancing the flywheel assembly

Next job in line is balancing

Here’s the S&S static balancing stand, it needs to be level to get an accurate balancing job.

The procedure weigh all the rotating and reciprocating parts in the bottom end assembly and using a formula that involves a “balancing factor” determine the weight of a “bob”weight to bolt to a flywheel. Each flywheel is balanced separately.

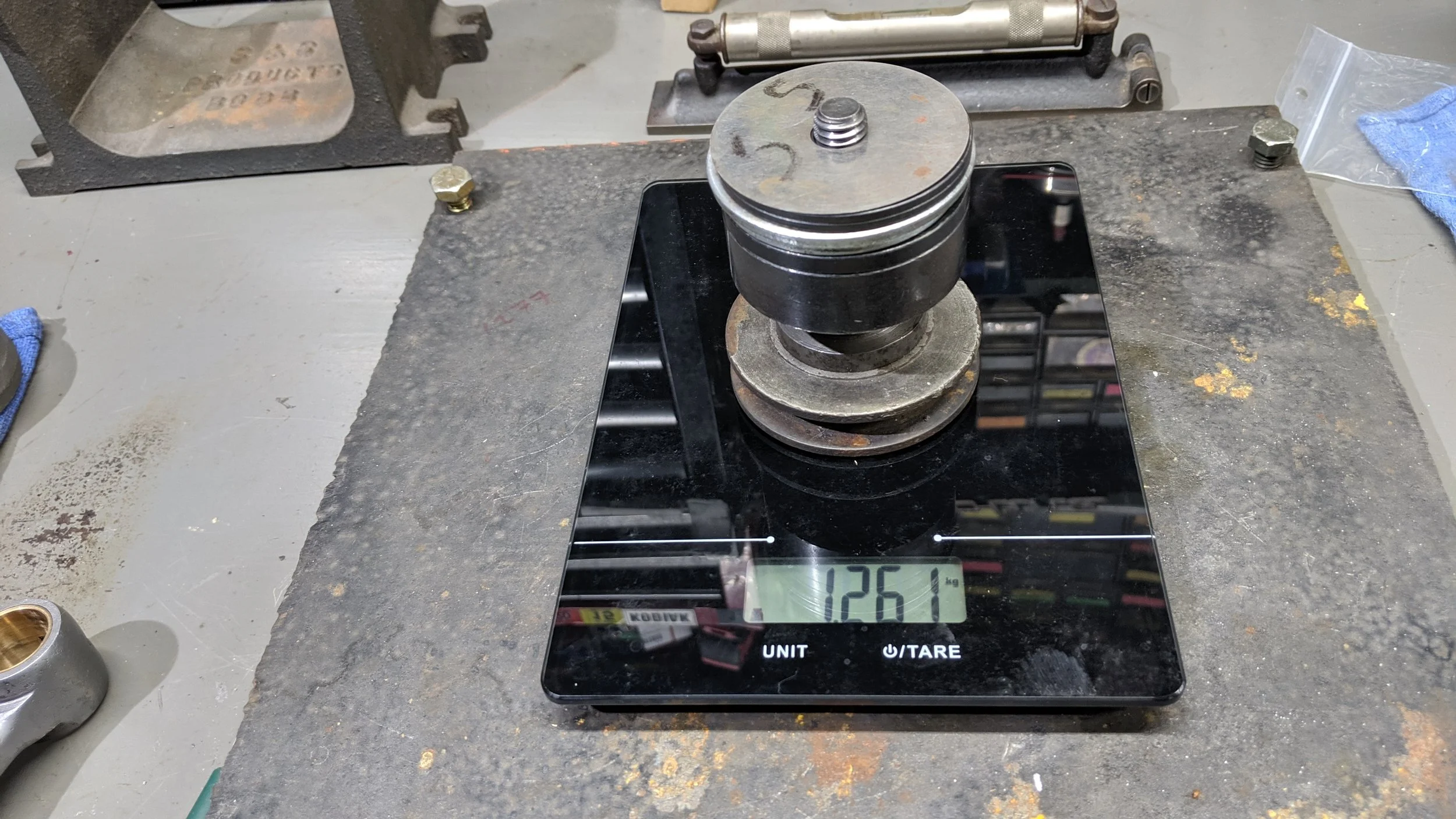

Here’s the components of the bobweight used in figuring how much weight to trim from a flywheel so that the flywheel will be trimmed to match the calculated weight. The object is to balance the flywheel so that when the various engine components are assembled to the flywheels and the engine is running, at a particular calculated engine rpm range the rotating and reciprocating forces on the flywheels will balance each other out and there will be minimal vibration coming out of the engine. Ideally, that rpm range will be the one the motor most often operates, say 50-60 miles per hr in top gear.

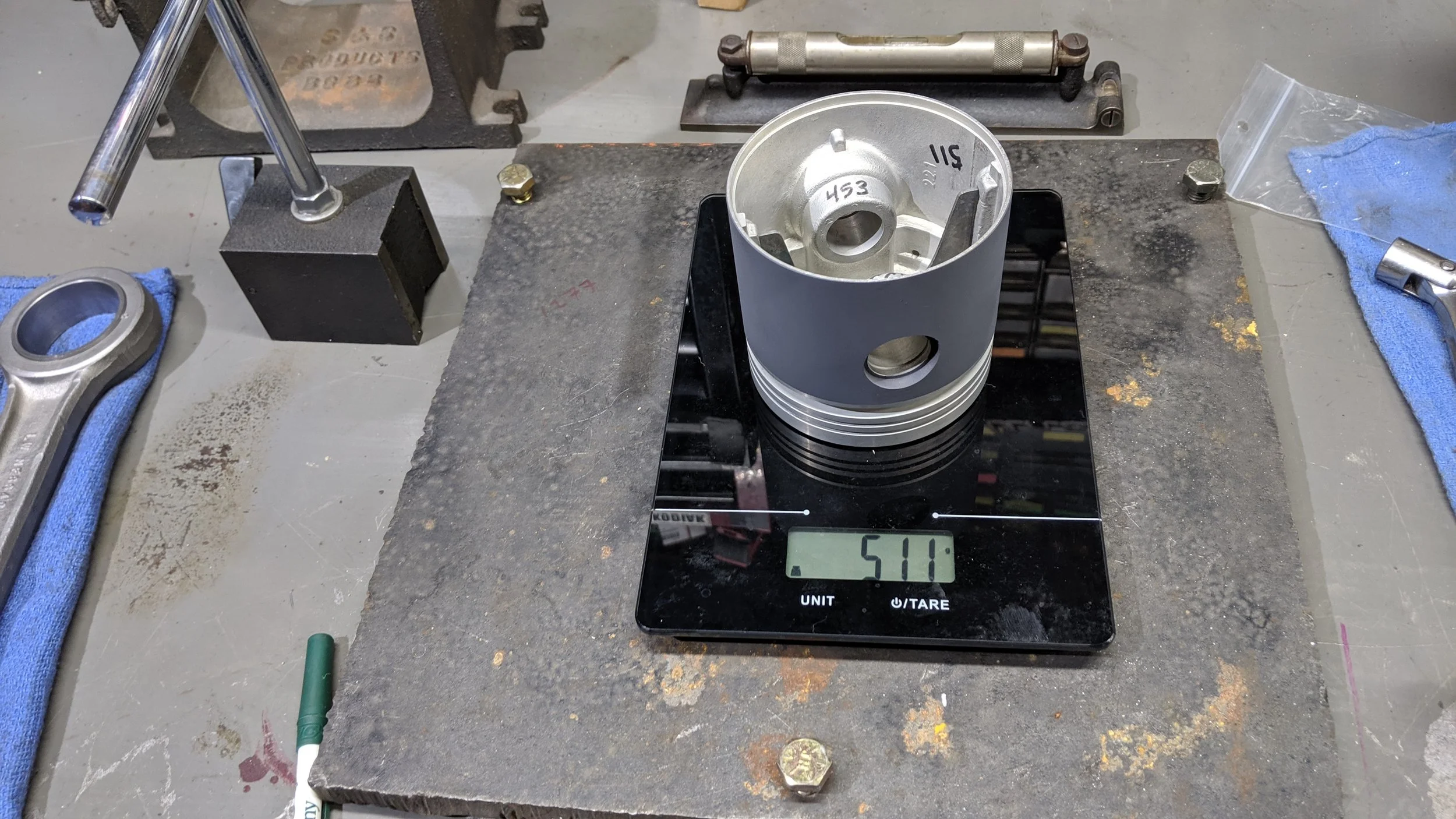

This piston weighs in at 511 grams, the other piston weighed exactly the same! Good quality control.

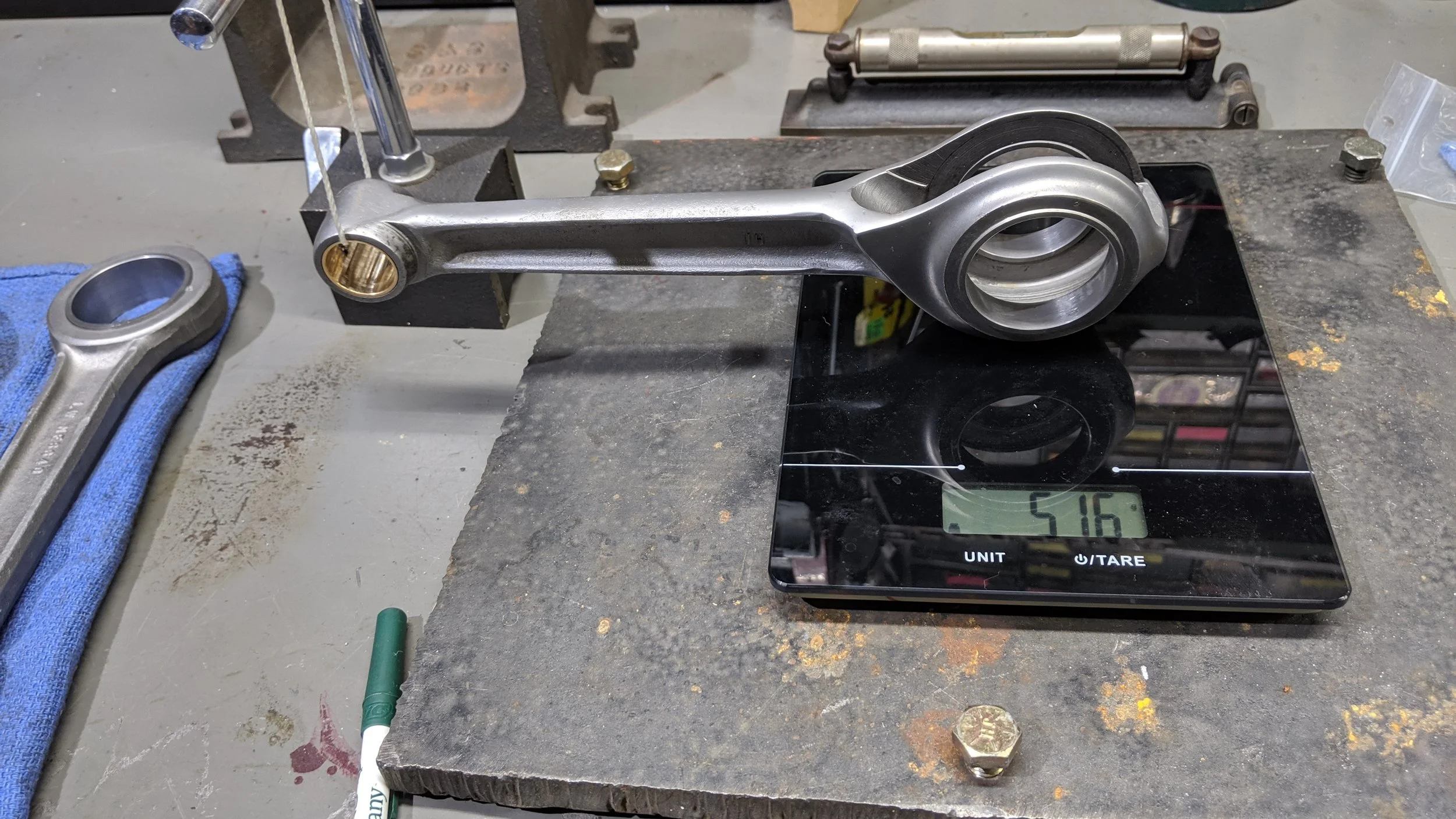

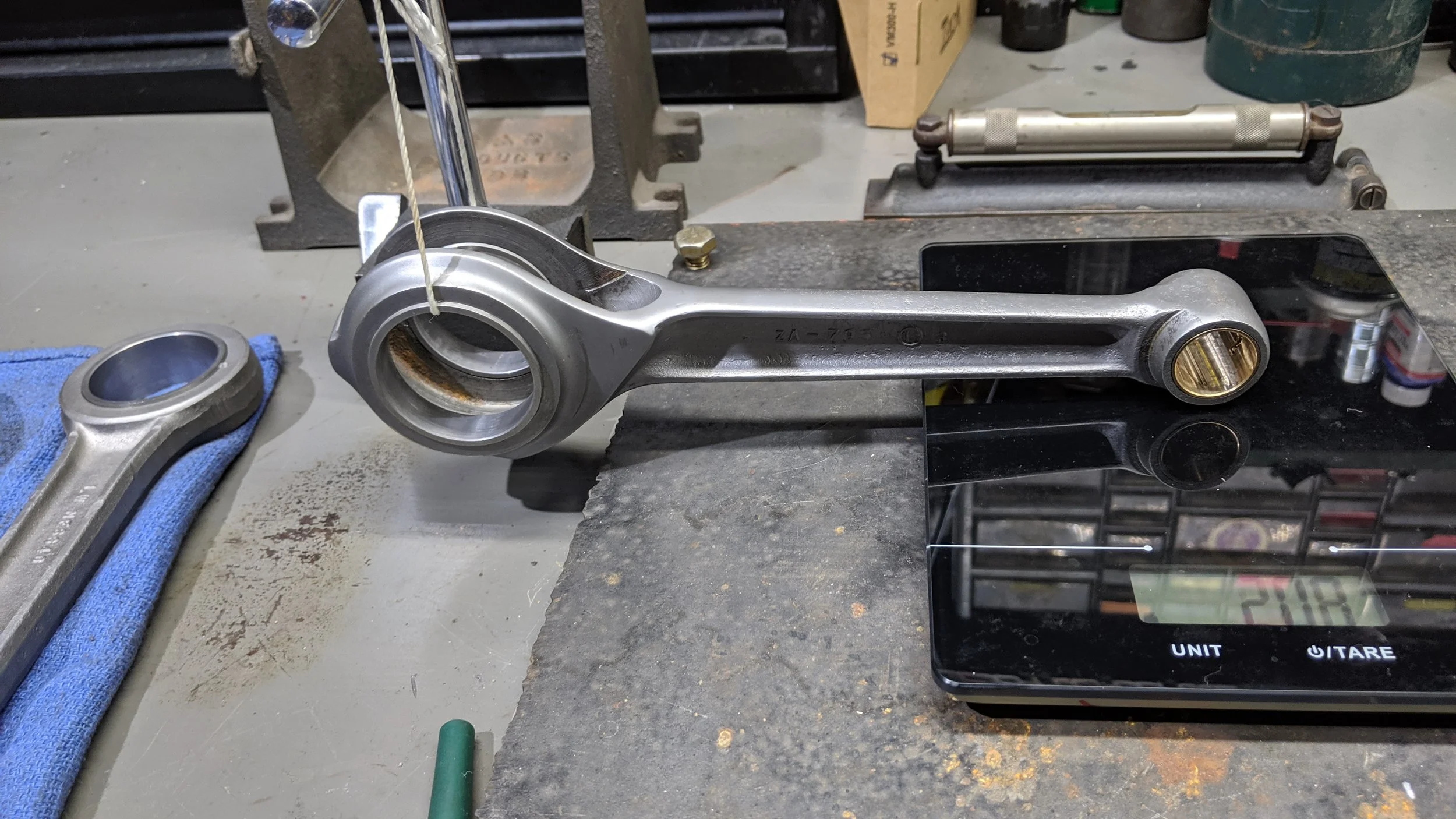

The connecting rods were next weighed, and it was necessary to calculate the weight of both ends of the rods, big end and wrist pin end. Ideally, after weighing, the sum of the two ends equals the total weight of the rod.

Weighing the rod bearing end of the female rod, the rod is suspended so that only the rotating end of he rod’s weight is measured.

And now, the wrist pin end of the connecting rod being weighed. This will be used as a weight for the reciprocating weight portion of the rod in our calculations

We also weighed the wrist pins, keepers, rod bearings, and cages. Wrist pins and clips and pistons going in the tally as reciprocating weight along with the upper end of the connecting rods, and the bearings cages and crank pin being tallied as rotating weight.

On a V twin motorcycle on a common crankpin, both piston/rod assemblies are lumped together as one sum weight and used to calculate the weight for the Bob weight. That’s what we did here, then divide that weight in half, and balance each flywheel separately with a bobweight weighing that Half weight.

Here’s the pinion side flywheel on the S&S truing stand.

The object is to drill holes in the flywheel along the periphery to bring the flywheel to balance at any point. You drill holes in the flywheel to lighten it to bring it into balance. You can see two holes on the upper right side of this flywheel, these were made by the factory back in 1938 when they balanced it. We had the rare occasion on this build to have flywheels that had always been kept as a pair and had not had their factory balance adjustments altered. By working backwards from the weight that these wheels balanced with, I was able to determine the original factory weight and fine tune the wheels to that balance weight. S&S normally recommends a balance factor of 60%, but this way, I was able to duplicate the factory’s original calculations.

Adding some supplementary drillings to fine tune the wheel’s balance

Again we added some supplementary to fine tune the flywheel’s balance..

The bob weight we used may look as if some of the pieces came out of somebody’s junk box, and your right, they did. S&S’s kit didn’t come with a fixture to fit the flywheel crankpin taper for Big Twin flatheads. So I cut a piece of bar stock and shrunk a pulley that had about the right weight to it and made my own. This bobweight has been on many sets of flathead flywheels.