Prepping Bottom end components

An old crankpin smeared with fine lapping compound

An old used crankpin with good tapers. Will use to lap in flywheels. Note the step in the crankpin diameter, Flathead and “61” crankpins differ from 74 pins which do not have the stepdown is size.

Here’s an old crankpin with good tapers we’re going to use to size the tapered holes in the flywheels. The flywheels although in good shape for being 80 years old could use the tapers for the crankpin being dressed. By rotating the flywheel on the tapered pin, it will tend to mate the 2 parts together for a better fit. And the engine depends on good fit between these parts to keep the bottom end rigid. After doing a preliminary sizing with this used pin, a final fitment will be done with the new pin that will go into the final assembly.

Pinion side flywheel on crankpin waiting for the cameraman to rock wheel back and forth in a lapping motion, much like a valve is rocked when being seated.

You can see the gray surface lapping leaves on the flywheel crankpin hole in this pic. You’re hoping to get a good mating surface here for pin and wheel to mate up

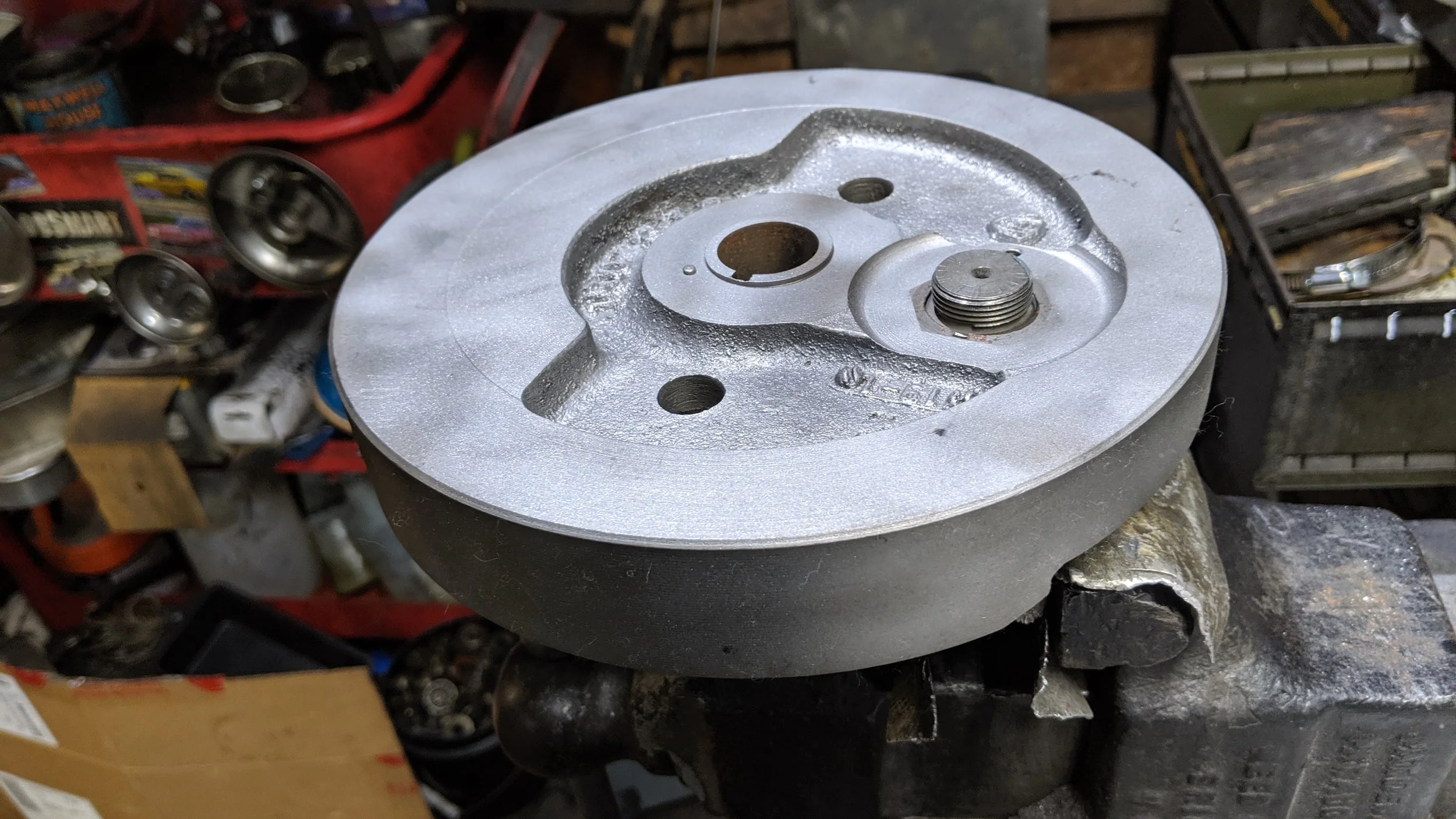

Sprocket shaft having been lapped into flywheel.

All 3 shafts that are going to be mated together have been lapped together, this isn't always necessary, but it’s good to check and this case, the flywheel tapers for the crankpin had some burrs on their edges, just from handling I suppose. After deburring I felt it was a good idea to go ahead and lap them as well.