Assembling and truing the 38U flywheels

First step is a rough alignment of the 2 flywheels

The 2 pieces of channel iron are connected by a piece of threaded rod, and hold the 2 flywheel assemblies in rough alignment

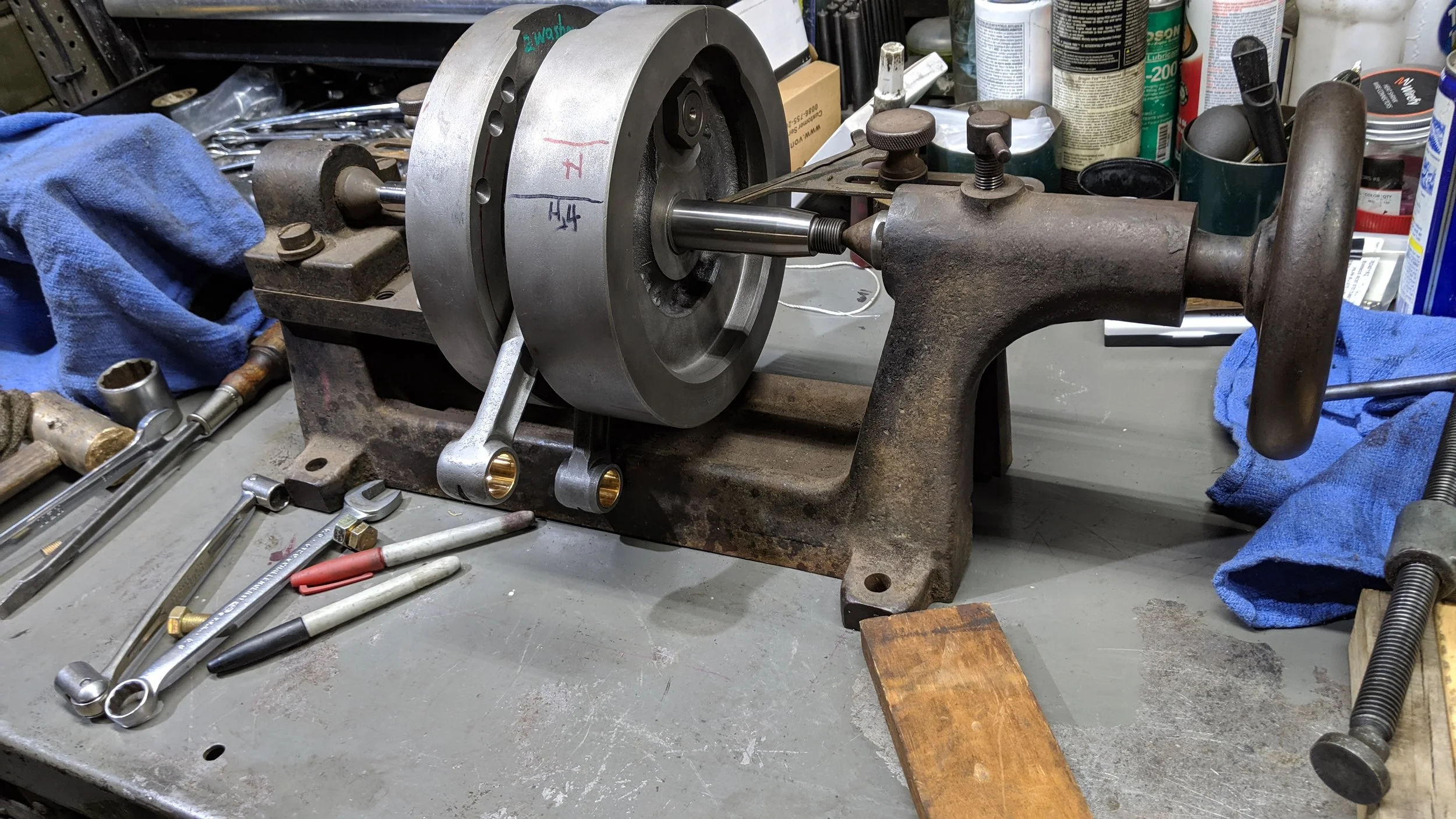

Here are the flywheels in my ancient HD truing stand, I got it from a BSA dealership that closed down many many years ago. Have no idea where a BSA dealer got the Harley tool, but anyway it does the job. The markings on the wheels indicate whether the spot is high or low, and how many thousandths. You mark the hi spots, and then wack’em with your hide hammer (another harley tool) to get them in alignment. If you get both wheels pinched together in the same area, you need to spread them. A wedge is often used to do this, but I made a nifty little tool yesterday

This is my wheel spreader tool, insert it between the flywheels, and turn the nut on the bolt so that they spread apart, and voila! it forces the wheels apart.

All flywheel adjustments take some educated guesses as to how far to spread, or how hard to hit them to cause a shift o the wheel (s). The assembly has spring to it and not hard enough, no change, they spring back. Too hard, they go further than you wished.